How To Check Or Test The Battery Machine Life

Battery Machine bikes are an excellent way to lower your Carbon Footprint; however, what should you look for in battery technology and motor manipulation systems? It is crucial to have information about what to have and what questions to ask. Choose the right motorcycle, and you may use it more excellent then. The financial, fitness and environmental advantages will make your investment in time and money adequately profitable.

Suppose the circumstance while you are on a romantic journey or a long drive and in the midst of the way, your vehicle breaks out because of the sudden battery harm. So what’s going to you right now? Do no longer panic, as we’re with you all the way and could permit you to understand a paranormal solution to take away this problem. Not anything else but a battery tester can only help you in this situation.

Battery testers

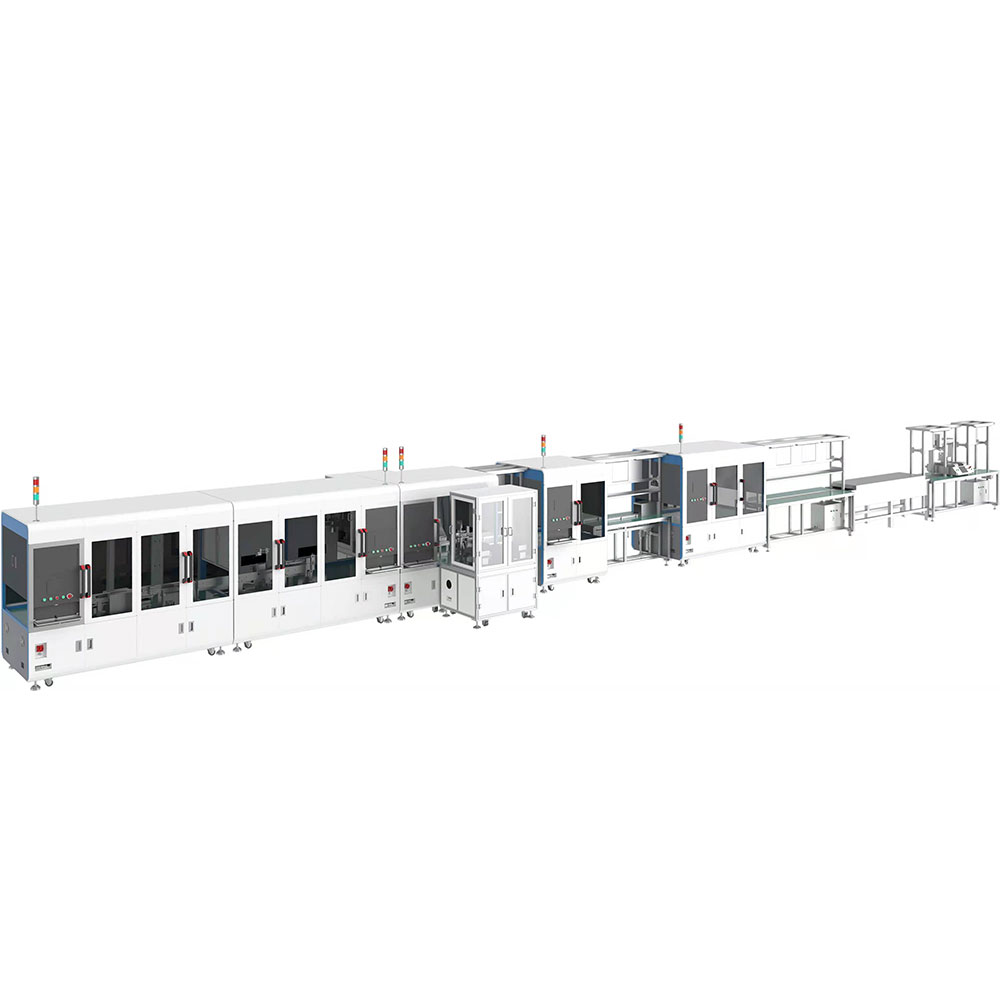

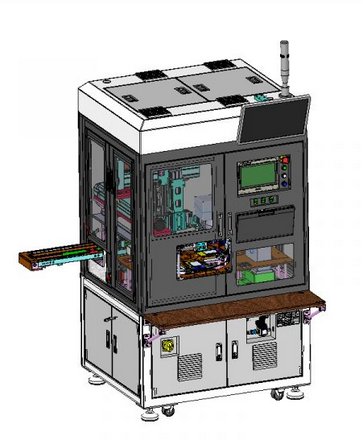

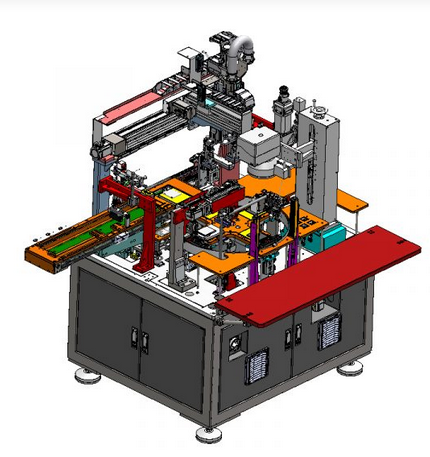

Battery Testing Machine can shield your vehicle or heavy-duty battery and protect to any breakdown because of the uncertainty. Those are tremendous devices that can screen the precise situation of your battery. These battery chargers can test the amount of charging, cranking, and cargo. It is a definitive answer for your battery problems, as you can understand the exact repute before taking up longer assignments with your vehicle and other home equipment.

Test the precise condition

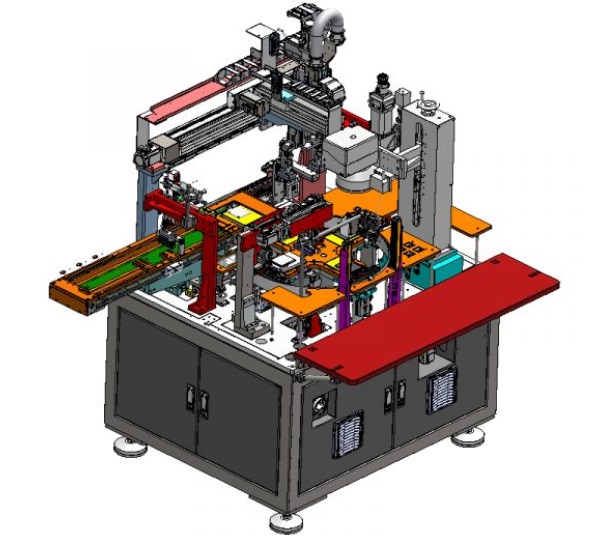

With those, you may look at the fortunate circumstance of the batteries assembled for your motorcycle, automobile, plane, and numerous other types of heavy responsibility machines. These are easy to apply, easy to understand, and are a hassle-unfastened way to make you knowledgeable ahead. Moreover, with the usage of the equal, you can keep away from surprising incidents. Moreover, it can offer you complete troubleshooting for your battery. Finally, it is the way can boost up the Battery Pack Machine using providing it input as and while required.

Easy-to-read display

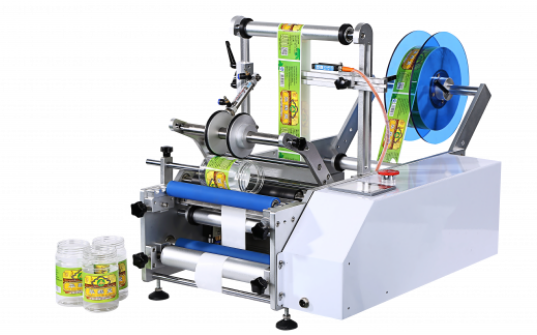

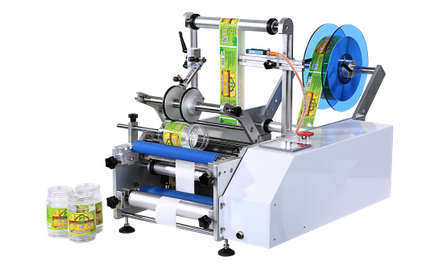

It generally has clean to read display, and the Wine Labeler tool can effortlessly be put into the lighter port. That is a user-pleasant instrument that is a worthwhile investment if made. The current markets have an abundance of these small but effective devices. The testers are more favored and liked adequately due to their several advantages. The compact design and glossy and contemporary fashions within the product range can serve your purpose.

Accurate battery testing results

You could recognize the underlying charging position and ultimately charge and discharge batteries. It could produce accurate battery trying out results in seconds. They can be received in virtual in addition to analog fashions, and you could select the one that fulfills your needs excellently. Via these great assisting hands, you may perceive the possible troubles and might take preventive measures as nicely.

Charging system diagnosis

You could look at load, recognize the battery circumstance, and discover the starter motor draw and whole charging device prognosis thru those. These may be used for several functions as alternators and special equipment. So don’t forget their benefits over again and upload those for your wishlist.

Get To Know More About Our Products:-

Battery Making Machine | Battery Cell Assembly Process | Battery Cell Assembly | Lithium Ion Battery Assembly | Battery Manufacturing Machine | Lithium Battery Assembly | Cell Pack Solution

Read More:-

Why Use Lithium Ion Battery Assembly for Power and What Are the Advantages?

Why Use Lithium Ion Battery Assembly for Power and What Are the Advantages?