LED Grow Lights Have Muchsignificance.

For the last half-century, the seasoned cultivator has employed creativity to deal with the undesirable byproducts of High-Pressure Sodium (HPS) bulbs. Growers that use older light fixtures are sometimes obliged to spend a lot of money on ventilation systems and let light control the development of their plants because of the surplus heat, energy, and spectrum emissions they produce.

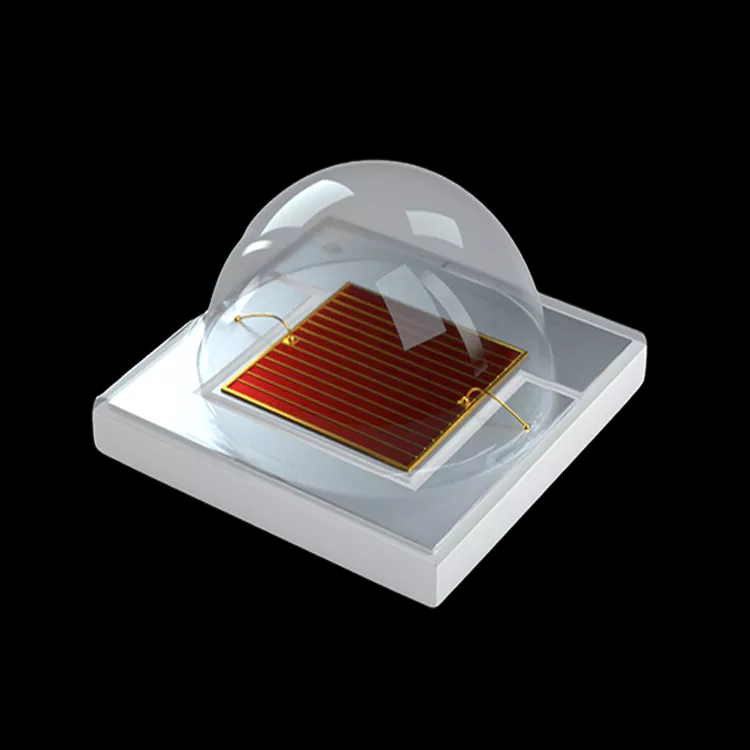

Thankfully, things don’t have to be this way anymore. LED technology, which uses the same amount of inventiveness to solve these problems, is constantly improving. LED Grow Light are specifically engineered to reduce energy consumption and the risk of burnt plants by maximizing spectrum and coverage. To put it another way, these lights aren’t chosen for the greenhouse; instead, they are selected because of the demands of the plants.

LED grow lights use 50-70% less energy than conventional methods while providing more focused light. Enhanced energy efficiency in operations reduces the environmental impact on the local community. LEDs lessen the emission and consumption of toxic compounds without sacrificing light quality.

The Full Spectrum LED lighting fixtures should last very long before the farmers need to consider replacing them. No need to stress about the environment being harmed when these lights are eventually discarded since they do not contain mercury. Using toxic pesticides and other chemicals on plants may be considerably reduced with the help of LED grow lights.

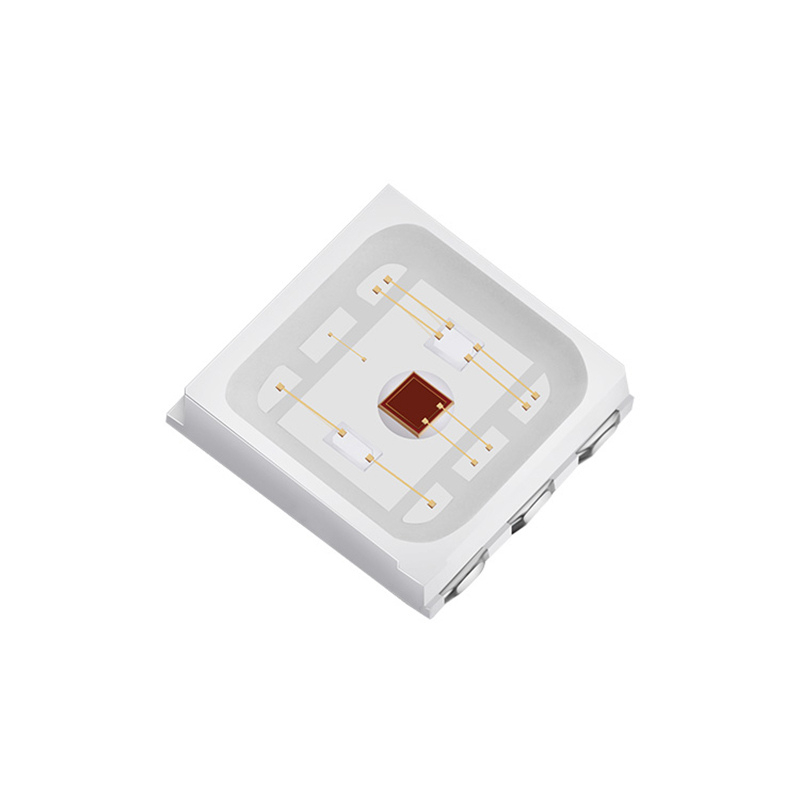

Every company always looks for ways to enhance operations to reduce costs and maximize revenues. Nearly 40% of the energy budgets of indoor cannabis farmers go toward lights. Grow enterprises may make significant strides toward optimizing their business operations by using durable LED lighting. Growers may count on LED 2835 as a reliable partner since the company provides a comprehensive selection of high-quality grow lights and expert support.

More information:

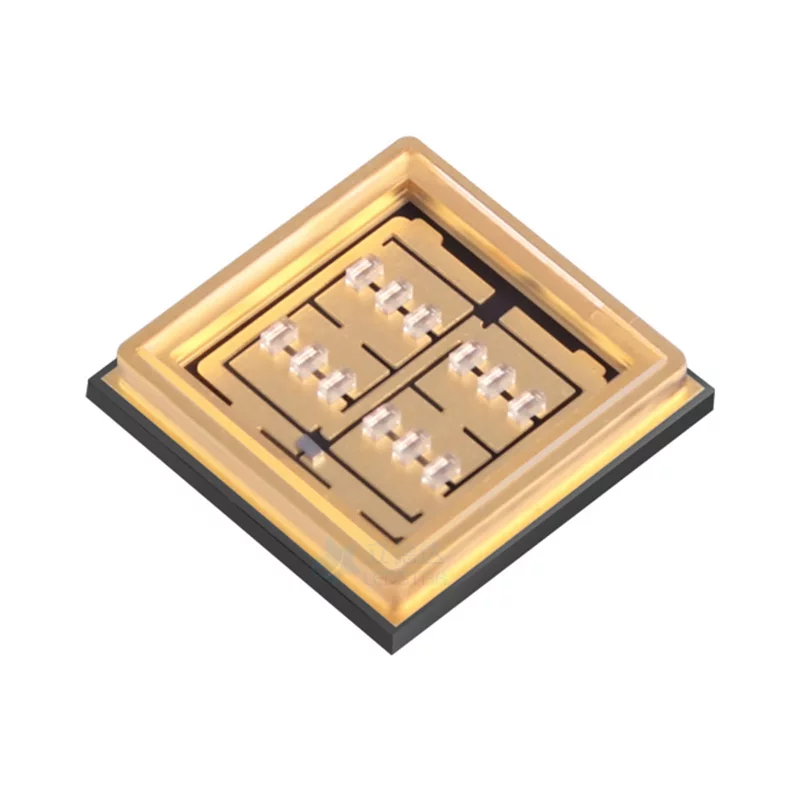

LED 405nm, LED 5050, LED Component, Full Spectrum LED, 365nm LED, SMD LED Chip, SMD Diode, Infrared LED