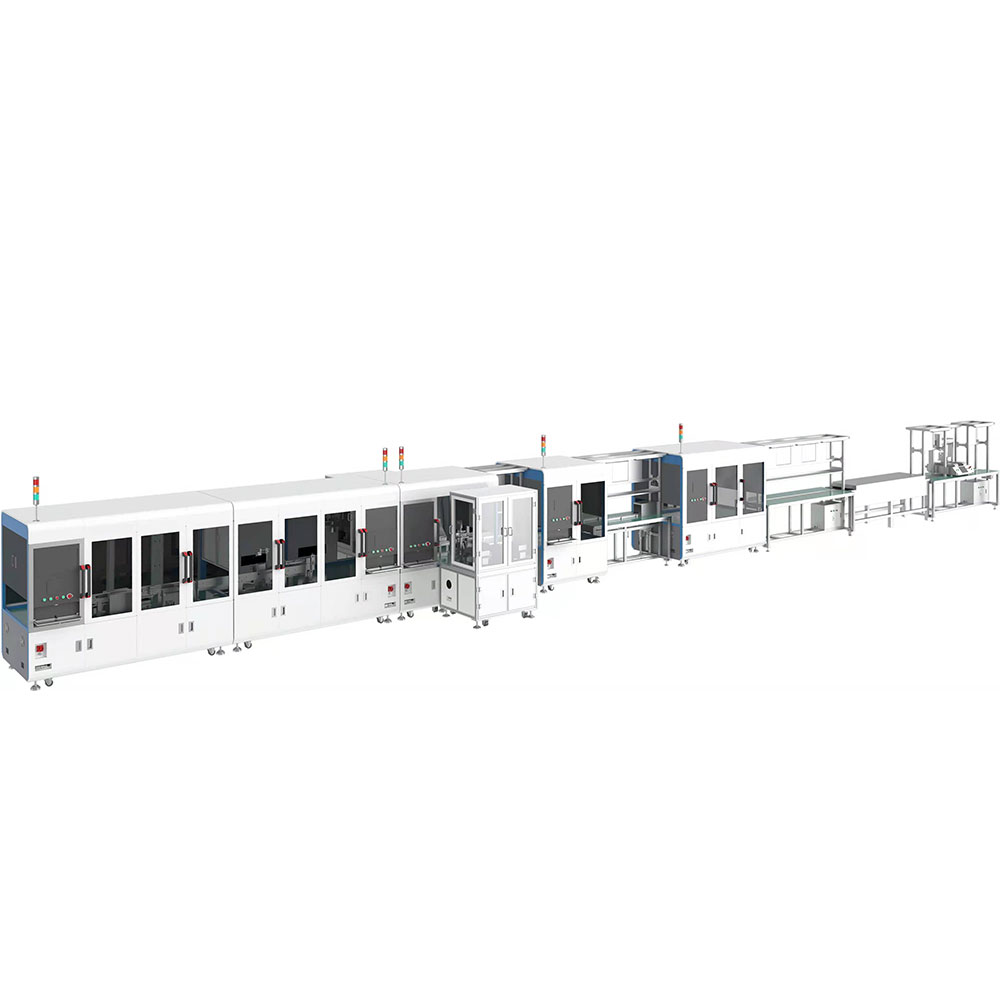

When choosing batteries, keep in mind that there is no one-size-fits-all solution. To choose the best battery for your application, you must first determine which battery characteristics are most crucial and then make a tradeoff between them. For instance, reducing internal cell resistance is essential if your application requires a lot of power, and this is often accomplished by increasing the electrode surface area. Energy density is sacrificed by increasing passive components like current collectors and conductive assistance to achieve this goal. While you may have big aspirations for the Battery Production Line‘s performance, you may have to compromise on some of your design objectives to make the battery work.

Differentiating Between Primary and Secondary Sources

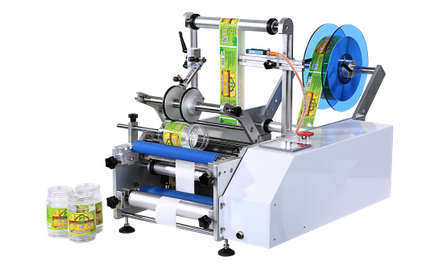

One of the first decisions to be make when choosing batteries is whether primary (single use) or secondary (rechargeable) batteries are need for the application. Usually, the designer will have no trouble deciding between these two options. Primary batteries are necessary for devices that are only used occasionally (like smoke alarms, toys, and flashlights) and for throwaway devices (like hearing aids, watches, greeting cards, and pacemakers), where charging is impracticable. A laptop, mobile phone, or smartwatch, for example, would benefit from a rechargeable battery because of the device’s need to continually power it for extended periods. Primary batteries like Wine Labeler‘s far lower self-discharge rate make them a suitable choice when charging isn’t an option or is impractical before the first usage. It’s common for secondary batteries to discharge rapidly. Due to recharge ability, this is less of a concern in most settings.

Comparing Energy and Force

The capacity of a battery, measured in milliampere-hours (mAh) or amp-hours (Ah), is the maximum discharge current it can provide for an extended period and determines the battery’s runtime. Energy content is a helpful metric to utilize when comparing batteries of various chemistries. Using the battery’s capacity in ampere-hours (Ah) and voltage, we may calculate the battery’s energy content in watt-hours (Wh). While both a 1.2 V nickel-metal hydride battery and a 3.2 V lithium-ion battery have the same capacity, the increased voltage of the lithium-ion battery increases its energy. Open-circuit voltage, or a battery’s voltage while not connect to a load, is often employ in energy calculations. However, the drain rate has a significant effect on capacity and energy.

Practical batteries only attain a small fraction of the theoretical values owing to the inclusion of inactive components and kinetic limits, even though theoretical capacity is determine only by the active electrode materials and the active mass. These accumulate on the electrodes, preventing their total usage, and hindering the effectiveness of the active materials.

Cost

Battery performance attributes are essential, but sometimes you must pass up a better option because the application is to price sensitive. It is particularly relevant when dealing with large quantities of throwaway products.

Physiological Makeup

The most common types of batteries are button/coin cells, cylindrical cells, prismatic cells, and pouch cells, although there are many more (most of them are standardize).

Conclusion

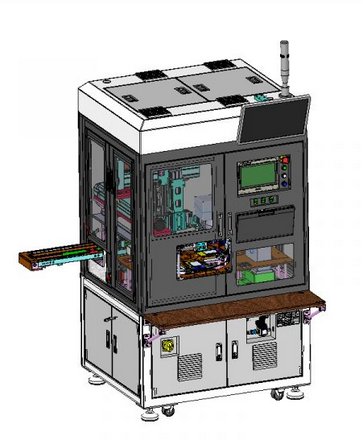

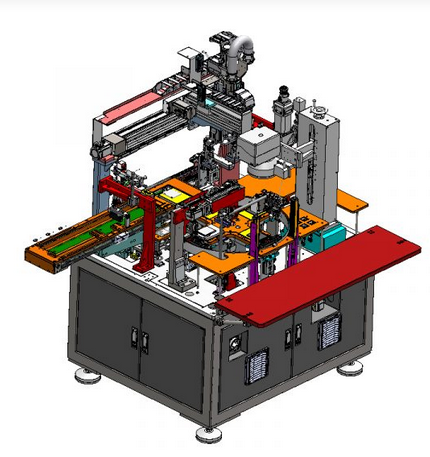

Choosing a battery welding machine involves numerous factors, as you can see. Several have to do with chemistry, while others concern battery design and construction. Because of this, comparing batteries based on their stated specifications is difficult at best and sometimes worthless.

More Products:- Battery Machine | Lithium Battery Assembly | Lithium Battery Welding Machine | Battery Assembly | Battery Production Lines | Build 18650 Battery Pack